BL-001-VF

-

Information

Outside dimensions

TYPE D W H BL-001-VF 395 400 650 ♦The filter vat has 2 types-standard and filter smoke.

♦The subject outlook and color can be customized

according to customer's request.

Product specifications

Model number UNIT BL-001-VF Horsepower HP 1/2HP 0.37KW Air flow m3/min 12 Air intake diameter m/m 150 Voltage V 220/380 Electric current A 1.5/0.87 Cycle HZ 50/60 Rotation R.P.M 2850/3500 Noise dB 65 Weight KG 36  ♦Design and specifications subject to change without notice.

♦Design and specifications subject to change without notice.Feature of Product

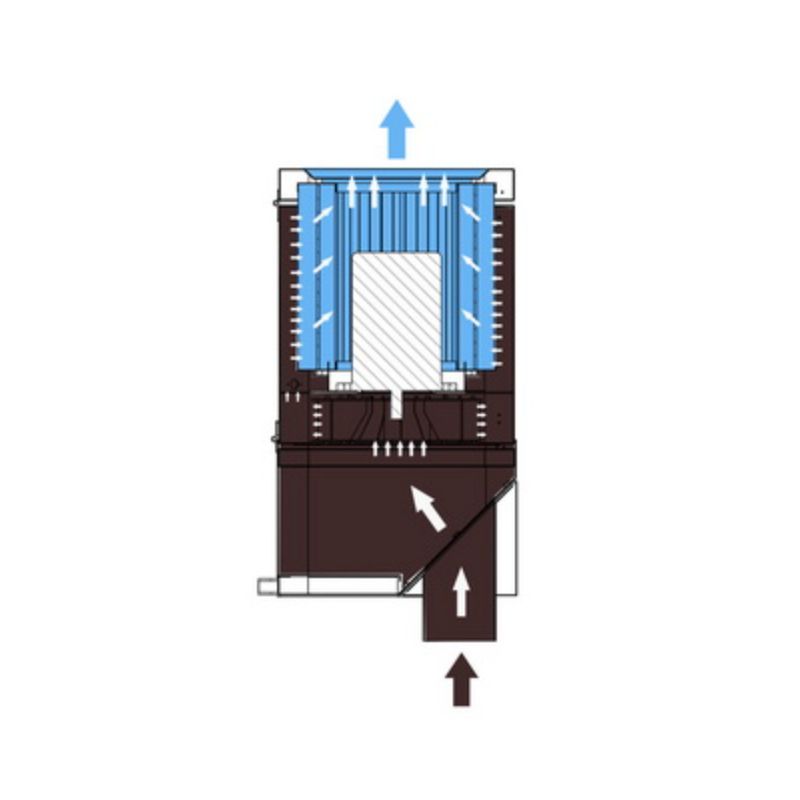

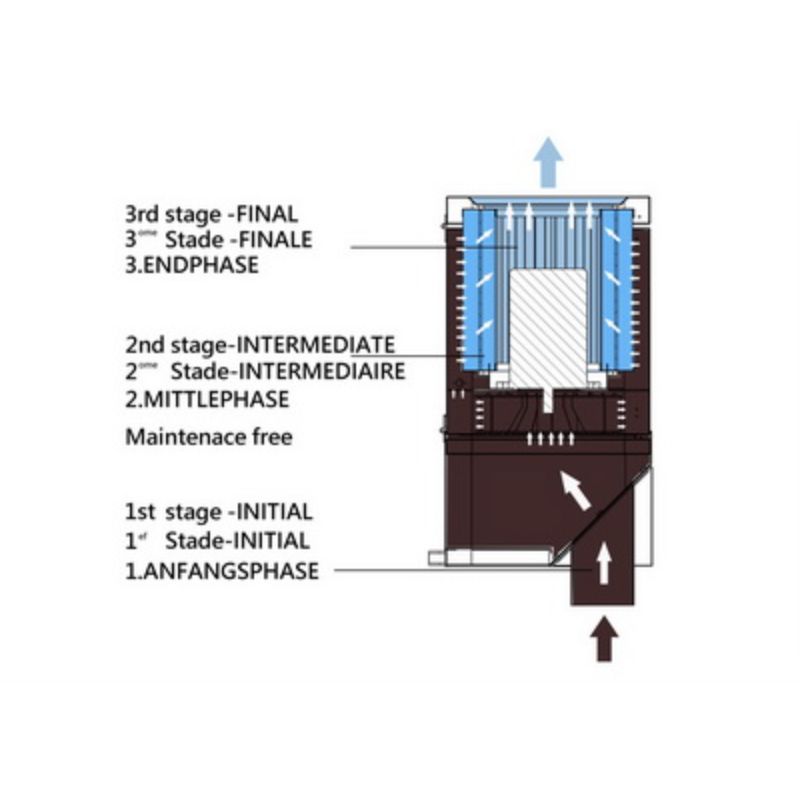

.Using the Centrifugal Fan Which has super strong attraction force and centrifugal force.

.With precise impeller design to reduce the motor load.

.The filter net is made by stainless steel material which has demisting, distrbution, with big

collection area and can remove the oil and mist effectively.

.It can collect an least 99% oil and mist, and then filter it for recycling.

.Washing the stainless steel filter net to avoid consumption, just clean at least once a year

Operating environment

This machine is suitable for use with integrated CNC machine tools as well as for oil vapor recycling within sealed operating environments. During machine tool cutting operations, oil vapor levels will rise with increasing spindle speed after cutting operations commence. This oil vapor can disperse into the operating environment. If workers inhale vapor over long periods of time, there could be serious health consequences, such as occupational disease. Accumulated oil vapor can also pollute the operating environment. Also, if the machine tool operating system is exposed to oil vapor long term it could increase the damage rate. Cleaning oil pollution from the operating environment is also another cost in time and effort. In order to respond to these problems, Bonli has developed this innovative new product.

Functions

After installing the mist and fume collector onto the machine tool, you are able to immediately recycle the oil vapor produced during machining. You are able to not only maintain a clean work environment, but also increase work efficiency. In addition to protecting your workers from occupational disease, you are also able to lower machining lubricant costs. Reduce your oil pollution cleaning costs and gain energy savings with an environmentally friendly solution. -

Q&A